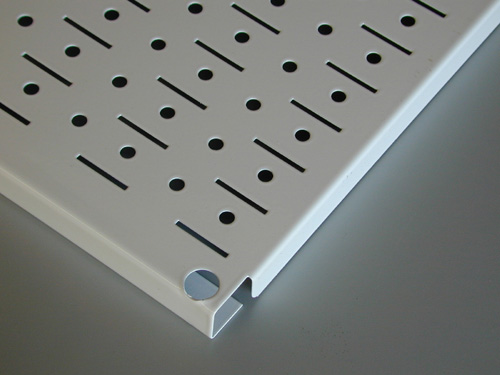

Wall Control’s fully formed panel edges allow for a quick,

secure, and frame-less installation on any wall or flat surface.

Unlike most other metal pegboard systems, Wall Control goes

the extra mile and provides a fully formed return flange in the back of our

full sized panels. This second bend in the panel’s flange allows for the

returned flange to mount flush with the wall or surface you are attaching the

panel to.

There are five major advantages to having a fully formed flange

on your pegboard panels. We will highlight each major advantage below which

includes Easy Installation, Panel Strength and Rigidity, Load Bearing Capacity,

Aesthetic Appeal, and Increased Storage Area.

1. Easy Installation

The formed panel edges eliminate the need to add a framework

to space the panel face off of the wall. Conventional “sheets” of pegboard

require a framework to mount to so that the panel face is spaced off the wall

properly, making tolerance for the back of the hooks and accessories to pass

through. With Wall Control panels, this functionality is built into the system

so all you have to do is take the panels out of the box and attach them to your

wall. No framework required!

2. Panel Strength and Rigidity

The formed flanges found on all Wall Control pegboard panels

creates a very rigid structure unlike what you would find if the panels were in

“sheet” form. Sheets tend to bow and flex very easily because they’re structure

lends them no physical material constraints. By adding formed edges we are able

to create a very rigid and strong structure that will not be prone to any

bending or flexing.

3. Load Bearing Capacity

The fully formed return mounting flange in the back of the

Wall Control full sized panels allows for the mounting screws to tighten flush

against the surface the panels are being attached too, as opposed to the panel

face itself. This is an important feature and distinction because many other

pegboard systems require the mounting screws to pass through a peg hole and

mount flush with the panel face which is separated from the wall. This

separation from the wall to the screw head on the panel face creates torque in

the mounting screw and reduces the load bearing capacity of the panel overall. Being

able to screw the mounting screw all the way flush with the wall eliminates the

extra torque on the screw and increases the weight the overall panel can

support.

4. Creates a Sleek Panel Face

The fully formed return flange allows for mounting screws to

be hidden from sight on the surface of the panel face. When a Wall Control full

sized pegboard panel is installed you will not see a panel face littered with

screw heads on the face of the panel, they will all be “sunk” into the panel

and flush with the wall for a sleek, clean finish to your storage and

organization area.

Additionally, by creating the flat return flange in the back

of the Wall Control panel the user does not have to tighten an exposed, sharp

panel edge to their wall and risk permanent damage to their mounting surface in

the event they want to relocate their panels in the future.

5. Increased Storage Area

Because Wall Control mounting screws do not require the user

to forfeit peg holes for mounting hardware installation, the panel face is 100%

ready for storage & organization once the installation is completed. Unlike

other systems, which force the user to pick and choose peg holes to sacrifice

for mounting screws, Wall Control panels are ready to have every square inch

utilized with pegs and tool board accessories.

The fully formed pegboard edges on Wall Control’s full sized

tool board panels are just another reason why Wall Control is first in class

when it comes to pegboard tool storage and home organization.

It should be noted that Wall Control’s pegboard “strips” do

not include the returned flange in the back of the strip simply due to their

small size and lower strength demands. Wall Control pegboard strips still

feature a flange that makes installation a breeze, requires no framework, and

increases strip strength and rigidity but this flange is not returned to mount

flush with the wall because the narrow dimension on the pegboard strips do not

require them as they are not a limiting factor in panel strength.

Shop Online at www.WallControl.com

Comments

Post a Comment